Manufacturing Process

- Optimize every process

Why DecoCan Excellence in Manufacturing

High Capacity

Efficient and quality manufacturing with advanced processes and equipment at DecoCan meets large-scale order demands.

Standardized Workshop

DecoCan ensures product consistency and stability through strict adherence to industry standards and procedures.

Strict QC

Comprehensive testing and rigorous quality evaluations underpin every DecoCan product.

Cost Control

DecoCan optimizes production for cost-effectiveness, offering quality products at competitive prices.

- Our Manufacturing Process

Welcome to DecoCan Tin Manufacturing

At DecoCan Tin Packaging, we believe in transparency and excellence. Our manufacturing process is a testament to our commitment to quality, sustainability, and innovation.

Crafting Excellence

Concept to Reality

Quality Control

sustainability

- Tin Packaging Design

Design and Development: Crafting Excellence

Our Philosophy:

In the realm of tin packaging, design and development are not just steps but an art form. At DecoCan, we blend creativity with functionality to create packaging that not only protects, but also enhances the product it holds. Our design ethos is centered on user experience, sustainability, and aesthetic appeal.

Our Process:

The journey from an idea to a tangible product is exhilarating. It begins with our team of skilled designers brainstorming and conceptualizing, followed by rigorous market research. We then move to the drawing board, creating prototypes that are both innovative and practical. Our development process involves multiple stages of refinement, ensuring every design meets our high standards and client expectations.

- Our Manufacturing

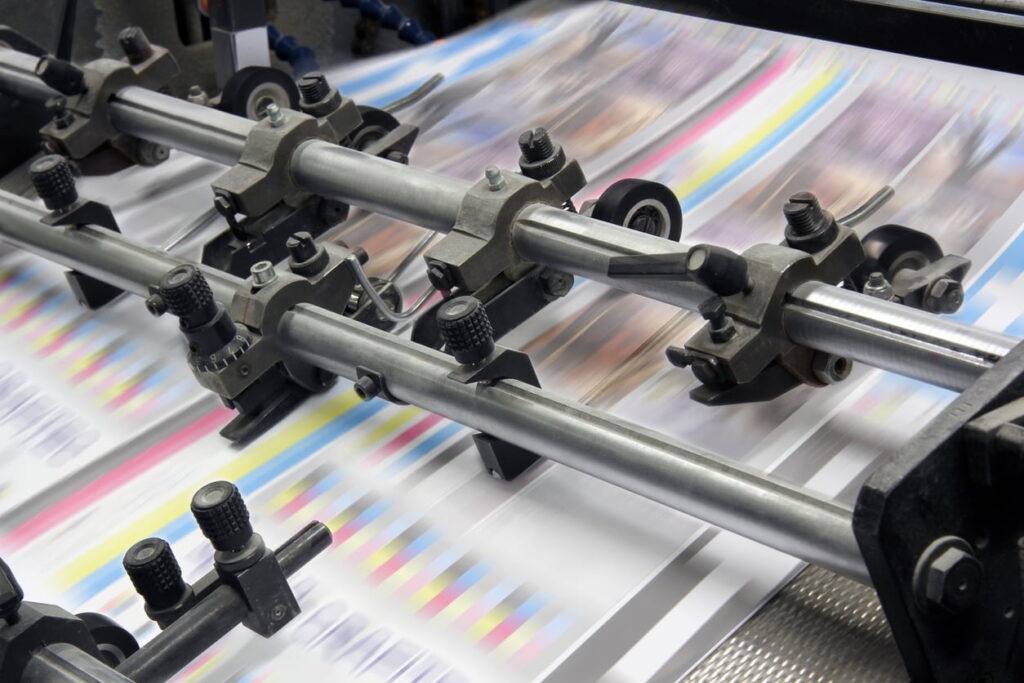

Production Process: From Concept to Reality

Our production line is where our designs come to life. The process is a symphony of precision and efficiency.

Sourcing Materials:

We start by sourcing high-quality raw materials, ensuring they meet our sustainability criteria. Our suppliers are carefully chosen for their commitment to environmental and ethical standards.

The Production Journey:

From cutting and shaping the tin to welding and painting, every step is carried out with the utmost care. We utilize state-of-the-art machinery and technology to ensure accuracy and efficiency. Our production line is a testament to our commitment to craftsmanship and innovation.

- DecoCan QC

Quality Control: Our Promise of Excellence

Quality is not an act, it’s a habit. At DecoCan Tin Packaging, we don’t just manufacture; we assure quality at every step.*

Setting High Standards:

Quality for us is non-negotiable. We adhere to international standards and have established strict internal quality control procedures. Our team conducts thorough inspections at every stage of production, from raw materials to the final product.

Ensuring Consistency:

Our state-of-the-art equipment and skilled workforce ensure that each product meets our high-quality standards. We regularly calibrate our machines and train our staff to maintain consistency in production. Our dedication to quality is reflected in the durability and aesthetics of our tin packaging.

- Our Responcibility

Environmental Measures: Sustainability in Action

At DecoCan, we understand our responsibility towards the planet. Our manufacturing processes are designed to minimize environmental impact.

Eco-Friendly Practices:

We implement sustainable production practices, including using recyclable materials and optimizing energy use. Our waste reduction strategies involve recycling scrap materials and efficiently managing resources.

Commitment to the Environment:

Our environmental measures go beyond our production line. We actively participate in eco-friendly programs and continuously seek ways to reduce our carbon footprint. This commitment is part of our mission to be a responsible and sustainable business.